Sappi had a tough second quarter but its US prospects look bright

Paper and pulp manufacturer Sappi’s operating performance for the second quarter of its 2025 financial year fell short of expectations owing to challenging market conditions and issues that arose during scheduled maintenance shuts, CEO Steve Binnie reported on May 8.

This resulted in adjusted earnings before interest, taxes, depreciation and amortisation (Ebitda) of $107-million for the period, down from $180-million in the second quarter of the prior financial year.

He said the challenging market conditions prevailed across all segments, driven by heightened uncertainty from potential global trade tensions and a broader economic slowdown, which placed downward pressure on selling prices.

Sappi reported a loss for the period of $20-million, compared with a profit of $29-million in the same quarter last year, while net debt went up to $1.67-billion from $1.37-billion.

Adjusted earnings per share (EPS) amounted to $0.01, down from $0.12 last year owing to the challenging market conditions and the adverse impacts of the one-off operational challenges experienced during the quarter, Binnie said.

The forestry fair value price adjustment for the quarter was a loss of $17-million.

Despite the various headwinds, Binnie said sales volumes remained stable year-on-year, with a modest recovery in packaging and speciality papers volumes, underscoring the long-term potential of these markets.

While market conditions for graphic papers remained soft, targeted efforts to grow market share delivered positive year-on-year gains, he said.

Amid these macroeconomic challenges, Binnie explained that Sappi had remained focused on optimising asset use and advancing cost-saving initiatives to support future performance.

The quarter was negatively impacted by issues that arose during the scheduled maintenance shuts of Sappi’s South African facilities, which required additional repairs and extended the shutdowns beyond the planned timeline, thereby reducing production for the period.

This resulted in an additional financial impact of $13-million over and above the $45-million guidance. Binnie assured shareholders that these issues were resolved and that both the Saiccor and Ngodwana mills were now running well post startup.

The quarter was also affected by the extended shut for the conversion and expansion of the Somerset Mill PM2 in North America, which was $20-million, in line with guidance.

“Given the uncertainty in our markets owing to ongoing global trade tensions and their broader indirect effects on macroeconomic conditions, particularly the tariffs imposed by the US on textile and apparel manufacturers in China which is impacting demand and pricing for dissolving wood pulp (DWP), we are adopting a cautious outlook and estimate that adjusted Ebitda for the third quarter of the 2025 financial year will be at a similar level to that of the second quarter,” Binnie said.

Demand for DWP remained steady during the quarter, but the typical seasonal boost in demand post Chinese New Year was not observed as textile and apparel markets slowed on the back of increasing geopolitical trade tensions and macroeconomic uncertainties, Binnie explained.

Viscose staple fibre (VSF) pricing consequently came under pressure, catalysing a $70/t decline in the hardwood DWP market price, which ended the quarter at $900/t.

The profitability of the pulp segment was negatively impacted by the lower production at the Saiccor and Ngodwana mills during the quarter. Although market prices dropped during the quarter, the net average selling price for the segment was above the equivalent period last year.

However, this positive year-on-year sales price momentum was offset by the lower sales volumes and increased costs resulting from the extended maintenance shuts, Binnie explained.

Sales volumes in the packaging and speciality papers segment increased by 9% year-on-year, reflecting a normalisation of inventory levels and modest recovery in demand in North America and South Africa.

However, overall global demand remained subdued owing to persistent macroeconomic headwinds and weak consumer sentiment. Profitability was impacted by the extended maintenance shut at the Ngodwana Mill.

Graphic paper sales volumes remained relatively stable year-on-year, despite the ongoing structural decline in market demand, reflecting positive market share gains for Sappi.

The segment continued to operate in an oversupplied environment, with pricing largely influenced by cost dynamics rather than demand fundamentals, Binnie said, adding that downward pressure on selling prices negatively impacted the profitability of the segment.

ABROAD

Sappi reported that its European business remained under pressure owing to persistent macroeconomic weakness and the significant oversupply in paper markets.

While sales volumes were relatively stable year-on-year, margins were adversely affected by lower selling prices, the company noted in its quarterly results.

Nonetheless, the region continued to benefit from a focus on operational efficiency with variable cost savings contributing positively to profitability. Variable costs were 1% below last year driven by lower purchased pulp and wood costs, while fixed costs were 3% above the prior year owing to personnel cost inflation.

The profitability of Sappi’s North American business was adversely affected by higher costs related to the planned shut for the conversion and expansion of Somerset Mill PM2, combined with general production challenges early in the quarter.

Although these factors weighed on Sappi’s margins for the period, Binnie believed that the underlying fundamentals of the US business remained sound, with stable sales volumes compared with last year.

The average net selling price in the US was broadly in line with the prior year, with resilient graphic paper prices offsetting downward pressure in the packaging papers and high yield pulp segments.

Variable costs were 5% above last year primarily owing to higher energy and raw material usage costs associated with operational disruptions during the quarter and higher purchased pulp costs, which were partially offset by lower wood costs. Fixed costs were 2% above the prior year primarily owing to higher maintenance and personnel costs.

DOMESTIC

Sappi’s South African business experienced the most challenging quarter of all, as the planned maintenance shuts at the Ngodwana and Saiccor mills adversely impacted profitability.

“The shuts and subsequent startup took longer than scheduled and we experienced other production challenges during the period. As a result, production in the quarter was lower than expected. Despite the shuts, sales volumes were steady year-on-year, and the average net selling price was higher,” Binnie said.

The forestry fair value price adjustment for the quarter was a loss of R307-million. Variable costs were 11% above the prior year primarily owing to higher raw material use, specifically energy, owing to operational inefficiencies associated with the scheduled shuts.

Fixed costs were 27% above last year owing to higher personnel costs and increased maintenance costs during the quarter, Binnie said.

Special items reflected a net expense of $17-million, primarily owing to $12-million related to fire and other extraordinary events at Sappi sites, together with the final closure costs for the Lanaken Mill of $4-million.

US PROSPECTS

Binnie said the escalating tariff trade tensions initiated by the US against key trading partners had introduced a high level of uncertainty into the global macroeconomic outlook, which posed a risk to Sappi’s financial performance.

However, he noted the direct impact of the currently proposed US trade tariffs on the business to be relatively limited.

At present, less than 7% of Sappi’s sales volumes involve cross-border trade with the US, limiting its direct revenue exposure to tariff-related risks.

“Importantly, we maintain a strong domestic presence in the US, and the paper markets in which we operate are net importers. As a result, tariffs could present a strategic opportunity as downstream participants in the value chain may increasingly shift toward domestic supply.

“However, the disruption of trade flows related to tariff actions could contribute to global inflationary pressures which may materially weaken consumer demand across all of our key markets,” Binnie explained.

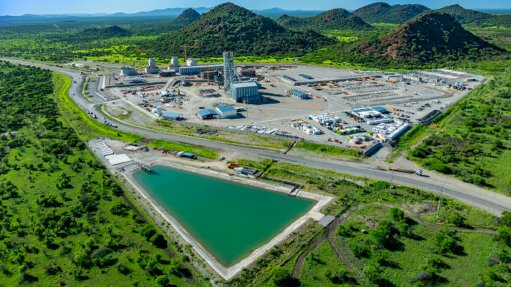

In the US, the company’s Somerset Mill PM2 conversion and expansion project was successfully completed in early May and machine commissioning is in progress.

“Our strategic focus for the packaging and speciality papers segment is to execute the commercial ramp-up of the PM2 machine, optimise our product portfolio mix and capture long-term growth opportunities as market conditions improve,” Binnie said.

He explained that the US was a significant importer of some of Sappi’s product categories, particularly graphic paper and packaging.

“Roughly 500 000 t/y of each are imported. The fact that we’re a domestic producer puts us in a stronger position, especially as a portion of that volume currently comes from Europe and South Korea.”

“To build on that, we’ve just completed the conversion and expansion of a machine in the US. As we now ramp up that machine, the added capacity and our domestic position could really help us capitalise on this shift in demand,” he explained.

The machine that Sappi converted was originally producing graphic paper, which is seeing a decline in demand, and has now been shifted to producing packaging, which is seeing demand growth.

“We’ve effectively doubled its capacity to 240 000 t. We believe we’re well positioned to take on additional demand. Of course, there are other aspects of the tariff environment that could be challenging, but in this context, it's definitely a promising opportunity,” he told Engineering News.

Despite the growing US market and ailing South African market, Binnie was adamant that Sappi would remain a fundamentally South African company for the forseeable future.

“We remain very much a South African company with a global footprint. Our headquarters are in South Africa, our strategic decisions are made here, and we have a strong local business. That said, we are constrained by the size of the South African economy and timber availability.

“We haven’t experienced any direct shareholder pressure to move our listing or headquarters at this stage. That said, the operational challenges are real. Going forward, growth is likely to occur faster offshore than locally.

“Therefore, from a growth perspective, it’s more likely that we’ll expand offshore, but our identity and headquarters will remain South African,” he said.

OUTLOOK

Binnie noted that the textile and apparel market, with its long and complex supply chain, was particularly vulnerable to ongoing trade tensions and inflationary pressures.

Moreover, he said inflation-driven constraints on consumer spending were likely to dampen demand for discretionary items such as clothing.

Binnie said demand for VSF and DWP in China had slowed in recent weeks as the value chain assessed the implications of the newly imposed tariffs.

“This has exerted downward pressure on pricing causing the hardwood DWP market price to drop to $847/t in early May. Despite current headwinds, our DWP business remains well positioned for sustained long-term growth,” he said.

Binnie noted that, despite current raw material costs being relatively low, potential global inflationary impacts associated with trade tensions posed a risk for Sappi’s input costs.

Maintenance shuts were scheduled for the Cloquet and Saiccor mills in the third quarter, which would have a negative impact on earnings of about $20-million. He said he expected the forestry fair value price adjustment would be negative owing to lower wood market prices in South Africa.

Sappi’s capital expenditure forecast for the current financial year has risen to $550-million owing to the delay in the startup, and substantially increased labour costs, associated with the Somerset Mill PM2 project.

“We anticipate that net debt will peak in the third quarter as the capital expenditure for the project is completed,” Binnie said.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation